1997 - Peter Houldcroft

The AILU AWARD for 1997

went to

Dr Peter Houldcroft

The picture above shows, Prof. Bill Steen presenting Dr Peter Houldcroft with the Association’s first Award on 8 October 1997 at the BAWA Leisure Centre in Bristol

In presenting the award, the President, Prof. Bill Seen,pointed out that gas laser cutting today accounts for some 60% of laser material processing applications world wide: a multi-million pound business.

In accepting the award, Peter said it was with surprise and delight that he heard he been chosen. ‘It has been 30 years since I invented gas assisted laser cutting at TWI and 11 years since I retired, so I quite expected that the event would have been forgotten,’ he said.

‘The gas assisted laser cutting development was the beginning of the TWI work on laser technology. The groundwork for the idea began in 1966 when I visited what is now the Rover Company Research Station and saw the work they were doing with trimming pressings with the plasma torch. This was actually not quite fast enough and I was asked if there was any way the cutting could be speeded up. I thought of adding oxygen but this was impossible because the oxygen would have reacted with the tungsten electrode. Then, in the Spring of 1967, I saw the 200 W CO2 laser at the Services Electronics Research Laboratories at Baldock and realised that although the power was too low for welding it might be used for cutting. Remembering the panel trimming problem I had the idea of passing the laser beam down an oxygen jet. An apparatus was made and it was instantly successful.’

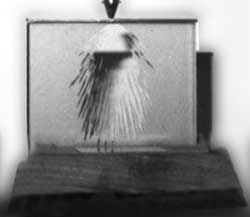

The award, a trophy sponsored by BOC Gases, is of a silver gilt cutting nozzle mounted

above a laser cut plate with a shower of sparks etched in the glass beneath.

It was designed and crafted by Julie Crossman, a London Silversmith

‘Early work was done with staff at SERL on the laser there but in 1968 I was able to persuade the Royal Navy to give TWI an up-rated version of the SERL laser on a permanent loan. It was designed to deliver 800 W, it never did, but was still 8 metres long! In those days laser output was very unpredictable and I often used to ring the laser lab and say “How’s the laser today?”

Peter’s only regret was that TWI never made anything from the patents. This was, he said, partly due to the parsimonious and inept behaviour of the now defunct NRDC, through whom the patents were filed, who could not be persuaded that the process had a commercial future. It was mainly a result, however, of what he still considers to have been shamefully partisan conduct on the part of the German Patent Court in Munich.