4 August 2008

Ophir-Spiricon Inc. Introduces Industry?s First Real Time, High Power CO2 Laser Beam Profiler

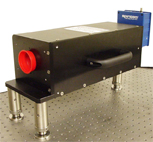

Ophir-Spiricon, the global leader in precision laser measurement equipment, recently announced the II-VI-CO2-58 Industrial Laser Beam Analyser. The II-VI-CO2-58 is a laser beam profiling system that enables the quantitative measurement and viewing of high power CO2 beams. The system diagnoses faults quickly, in real-time, and corrects issues related to beam stability, alignment, tuning, and optimisation.

Ophir-Spiricon, the global leader in precision laser measurement equipment, recently announced the II-VI-CO2-58 Industrial Laser Beam Analyser. The II-VI-CO2-58 is a laser beam profiling system that enables the quantitative measurement and viewing of high power CO2 beams. The system diagnoses faults quickly, in real-time, and corrects issues related to beam stability, alignment, tuning, and optimisation.

The II-VI-CO2-58 Industrial Laser Beam Analyser is a portable device that can be used to quickly and easily spot check performance on a variety of laser-based machines - in one or more facilities, or in the field. The system’s 58mm clear aperture enables the user to measure large laser beams. The ability to handle up to 10kW of power makes it ideal for high power CO2 lasers. With the ability to produce up to 48 images per second, users can view transient laser performance in real time. Other systems can take up to 10 seconds to create a single image and mask real-time transient responses.

The II-VI-CO2-58 Industrial Laser Beam Analyser is designed to work with the industry’s leading beam profiling camera, Ophir’s Pyrocam™ III. The Pyrocam III is a solid state camera based on one of the most rugged, stable, and precise IR detector arrays available. It delivers a 1000:1 linear dynamic range for high accuracy profiling. The camera offers 2D or 3D views of laser beam profiles, providing instant alerts about detrimental laser variations.

The II-VI-CO2-58 Beam Analyser camera connects to a PC through a FireWire interface for advanced analysis capabilities. A Basic Image Viewer presents 3D isometric plots and 2D color contour plots. The company’s LBA-PC-PIII software also works with the beam analyzer and contains all the algorithms and calculations necessary to make the most accurate measurements, including an ActiveX® interface for extracting data into other applications, 2D and 3D viewing, reference subtraction, user-customised apertures and colour palettes, and Z-axis scaling. “Until now, it was impossible to study the transient effects of high power laser processes in real time,” stated Ephraim Greenfield, VP Engineering, Laser Measurement Group, Ophir-Spiricon, Inc. “In a one half second CO2 weld, for instance, the part may burn one-third of the way through the weld. With the II-VI-CO2-58, you can see, in real time, when the laser beam is getting too small and too intense before the weld is complete. This allows for faster diagnosis of problems, a significant increase in quality parts, as well as lower scrap rates and less downtime.”

- Contact Information

- Name: Stuart Thomson

- Email: Stuartt@laserlines.co.uk