5 September 2008

LVD laser gives Mec-a-Tec flexibility and major cost savings

When orders for its specialist conveyor systems went up by 100% in a year, Wisbech-based Mec-a-Tec Services found that it was subcontracting out more and more laser profiling. By investing in an LVD Orion 3015 Plus 4kW laser cutting machine it not only brought control over the work back in house, it also achieved an almost immediate payback on its investment.

When orders for its specialist conveyor systems went up by 100% in a year, Wisbech-based Mec-a-Tec Services found that it was subcontracting out more and more laser profiling. By investing in an LVD Orion 3015 Plus 4kW laser cutting machine it not only brought control over the work back in house, it also achieved an almost immediate payback on its investment.

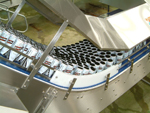

Mec-a-Tec is the only UK company to manufacture and supply a complete range of bespoke conveying equipment for beer and beverage can-making and filling plants – with around 70% of its production being exported to all parts of the world.

Like all of the can-making industry, the company went through a lean time in the late 1990s as supermarkets switched away from cans to other packaging methods. In the past three or four years though, demand has accelerated rapidly as market sentiment has changed and new markets have opened up in Eastern Europe and Asia. The company now has a full order book and is one of the most active suppliers to the two-piece can-making sector.

Thousands of different components go into each job and, as every line is tailor-made, the components for each line have to be designed and manufactured for that specific project.

Lead times are generally tight too. The process equipment tends to be ordered well in advance, but the conveyors are the last piece in the jigsaw. The supplier knows all the elements that need to go into the line and orders them first because they are on long lead times, then the supplier starts to piece together the layout and how it will fit in the available space – only when that is complete will the conveyors be ordered.

Paul Framingham, Mec-a-Tec’s Technical Director, says, “The strong market over the past three or four years has put a lot of pressure to succeed on the business – with increasingly technical projects and ever shorter turnaround times. The most important thing to our customers when they buy from us is that they have confidence that we can perform to the needs of the project. Technical ability combined with speedy deliveries are of the utmost importance – but budgets are always tight and costs have to be reduced wherever possible.”

Paul Framingham, Mec-a-Tec’s Technical Director, says, “The strong market over the past three or four years has put a lot of pressure to succeed on the business – with increasingly technical projects and ever shorter turnaround times. The most important thing to our customers when they buy from us is that they have confidence that we can perform to the needs of the project. Technical ability combined with speedy deliveries are of the utmost importance – but budgets are always tight and costs have to be reduced wherever possible.”

He says that the main justification for the investment in the LVD machine was the amount of time and money being directed into subcontract laser cutting, while ever decreasing lead times on projects requiring a lot of original design reduce the amount of time available for manufacture.

“Our punch press is ten years old, and it was the latest technology when we bought it. But technology has moved on since then and the punch press just couldn’t cope with the volume of work that we were doing, so we subcontracted it out. And as our turnover escalated we weren’t just using one subcontractor, we were using two or three.”

The move to laser cutting meant that there was no need for deburring or cleaning of components and also improved accuracy. It was also more practical than finding a subcontractor with the right tooling to punch out each job. But using subcontractors on this scale took a lot of time and effort to manage, adding another layer of cost on top of the actual processing.

“Drawings would be emailed, quotations received, purchase orders raised, materials delivered, goods collected and then sorted before folding on our press brake. We believe that the actual costs of having the parts subcontracted out was about 40 to 50% higher than the actual invoiced values. For around £100,000 a year of invoices we probably had £140,000 of real cost – so you look at that and realise that the payback on the LVD Orion was going to be almost instant,” says Paul.

“Drawings would be emailed, quotations received, purchase orders raised, materials delivered, goods collected and then sorted before folding on our press brake. We believe that the actual costs of having the parts subcontracted out was about 40 to 50% higher than the actual invoiced values. For around £100,000 a year of invoices we probably had £140,000 of real cost – so you look at that and realise that the payback on the LVD Orion was going to be almost instant,” says Paul.

“Since the LVD Orion 3015 Plus Laser was installed in October 2007 we have also seen a dramatic reduction in the amount of time spent by our stores personnel organising purchase orders, deliveries of sheet and collection and sorting of subcontracted parts. We have also reduced the amount of time that accounts spend reconciling delivery notes to purchase orders and invoices. Component design will undoubtedly change too as the machine allows greater manufacturing possibilities over conventional methods.”

As Mec-a-Tec’s Managing Director Ian Claxton explains, “We aren’t subcontractors so we weren’t concerned about having a fast, high-volume machine that would be working 24 hours a day, and the Orion provided exactly what we needed. I dare say we could have spent another £100,000 and got a machine that was twice as fast, but we didn’t need that. It is there for us to use to improve our business, decrease our lead times and increase our flexibility.

“The factors that are most important to us are production flexibility and time. When you are relying on another company you are in their hands when it comes to deliveries, and having a machine here gives us the flexibility we need. If something happens that needs turning round very quickly, then this machine can do it.

“We had to cope with a 100% increase in turnover from one year to the next and that was very difficult. Now we have the flexibility to increase it further – and we are saving £140,000 a year on subcontracting.”

- Contact Information

- Name: Chris Phillips

- Email: c.phillips@lvd.com