12 September 2008

Degating FR4 Circuit Boards

Synrad's sealed CO2 lasers are used in a variety of industrial processes including cutting, welding, drilling, and marking.

Synrad's sealed CO2 lasers are used in a variety of industrial processes including cutting, welding, drilling, and marking.

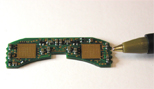

When using automated equipment to manufacture small PCBs (Printed Circuit Boards), it is far easier to fabricate boards and insert components while working with a single large board. PCB designers accomplish this task by nesting many smaller boards to fit within the confines of standard size boards. The first photo shows a partial view of a 20-up board where 20 smaller boards are contained within the larger parent board. After board fabrication and component insertion is complete, individual boards are cut from the parent board prior to integration into the final product.

The customer request for this application was to verify the feasibility of degating, or trimming, individual multi-layer PCBs from the parent board. Boards are held in place by four trim points on each end with the trim points measuring 0.775 mm (0.0305”) thick by 0.635 mm (0.025”) wide. The laser cutting set-up consists of a Firestar f400 laser mounted behind an XY gantry with 90-degree “flying optics” delivering the beam down to the focusing optic in our cutting head. A 63.5 mm (2.5”) positive meniscus lens was chosen with a 1.8 mm (0.07”) depth of focus based on the required spot size and board thickness. In addition, a supply of 4.1 bars (60 PSI) of air as a gas assist to blow vaporized FR4 through the cut kerf.

To assist the customer in determining the right laser solution for his budget and throughput requirements, tests were performed using both 200 and 400 watts of power. At the 200-watt power level, the FR4 trim points were cut through at a speed of 3.18 meters per minute (125 inches/min). Using 400 watts, the PCBs were cut out at a rate of 6.35 meters/minute (250 in/min). In both cases, cut edges exhibit the typical FR4 charring, however the surface area is too small to be readily noticeable or affect the PCB in any way.

- Contact Information

- Name: Gary Broadhead

- Email: garyb@laserlines.co.uk