29 September 2008

Laser Marking Glass Reinforced Plastic

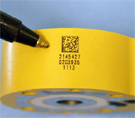

Glass-filled or glass-reinforced plastics such as polypropylene and ABS are commonly used in the manufacture of various electrical and automotive components. While the glass fibres primarily add strength to parts, they have the added benefit of helping to create highly contrasting marks in CO2 laser marking applications. The accompanying photograph illustrates the fine detail possible when laser marking a glass-reinforced plastic component. In this application, the overall mark size, 2D code and human-readable text, covers an area measuring only 4.25 mm by 7.28 mm (0.167” x 0.286”).

Glass-filled or glass-reinforced plastics such as polypropylene and ABS are commonly used in the manufacture of various electrical and automotive components. While the glass fibres primarily add strength to parts, they have the added benefit of helping to create highly contrasting marks in CO2 laser marking applications. The accompanying photograph illustrates the fine detail possible when laser marking a glass-reinforced plastic component. In this application, the overall mark size, 2D code and human-readable text, covers an area measuring only 4.25 mm by 7.28 mm (0.167” x 0.286”).

Using WinMark Pro, a 2D Data Matrix was created and stroke text objects using the same 18-character data string for both. To prevent the possibility of a data mismatch between the 2D code and text strings in a manufacturing environment, WinMark Pro allows the user to link two or more objects together using From Another Object and Assign From properties so that shared mark data always remains synchronised.

The Data Matrix code was sized so that it measured 3.6 mm (0.140”) on a side and set the 2D Barcode Bitmap property to No. This forces WinMark Pro to mark the code by drawing vector circles instead of raster-scanning filled and unfilled squares. In addition to decreasing cycle time, this feature allows the user to reduce circle diameter to eliminate potential print growth errors—in this case, the 2D Barcode Circle Radius property was set to 40% and achieved “B” grades using the barcode reader’s verification software. A the three-line human-readable text string was created using Simple stroke font with a Text Height of 1.04 mm (0.041”) and 0.13 mm (0.005”) of Extra Character Spacing.

The final step is to configure mark parameters. Because an 80 mm focusing lens was specified with its 116-micron (0.005”) spot for this application, only 10 watts of power was needed at a marking Velocity of 254 mm/second (10 inches/sec) to create the high-contrast text and 2D code objects shown in a cycle time of 0.44 seconds per part.

- Contact Information

- Name: Gary Broadhead

- Email: garyb@laserlines.co.uk