13 March 2009

High Precision Implant Production using Biocompatible Labelling

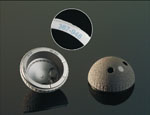

Apart from their precision fit and biocompatibility, implants and the toolsets necessary for their manufacture must be marked in a reliable and equally biocompatible manner. Production facilities running at high-precision allow for the manufacture of implants which are accurate down to a hundredth of a millimeter and the special processing of the surfaces guarantees biocompatibility, which is extremely important for implants.

Apart from their precision fit and biocompatibility, implants and the toolsets necessary for their manufacture must be marked in a reliable and equally biocompatible manner. Production facilities running at high-precision allow for the manufacture of implants which are accurate down to a hundredth of a millimeter and the special processing of the surfaces guarantees biocompatibility, which is extremely important for implants.

To achieve this laser marking units of the company NWL, Germany are used. To be more precise, these are units from the MISTRAL production series. These lasers have a high degree of flexibility and with their ease of handling they are simple to use. With the MISTRAL laser system a highly legible, permanent and above all biocompatible mark is generated on materials such as cobalt, chrome or titanium. Since no additives whatsoever are required for laser marking with the MISTRAL, this laser system is the ideal resource for labeling medical-technical products.

A number of positive aspects help the MISTRAL laser systems from NWL Laser Technology to stand out from other marking lasers. A highly flexible cabin, user software that is simple to use and an extremely reliable laser distinguish the NWL marking systems. Available with laser powers ranging from 8 to 50 Watts and outstanding capabilities in terms of flexibility due to its open architecture it can be easily integrated into new or existing assembly lines. Two different types of laser marking heads are available to accommodate various part orientations, marking applications and available space, Nd:YAG or Nd:YVO4, simply choose the one that best suits your specific conditions. In addition, the power supply units can be supplied in a standard 19" rack mount to fit into a wide variety of industrial cabinets. The MISTRAL has a well designed protective housing and although a Laser Class-l device is a versatile, compact and mobile system with outstanding performance features. Pull the marking cabinet to the forward position and you have an ergonomic seated work station. Or, separate the marking cabinet from the lower supply housing to integrate into your automated assembly line. As well as the many standard features there are many optional components available such as part feeding units or semi automated part supply devices. The small footprint of the MISTRAL lets you easily find a suitable place for your laser marking system and is very portable due to its integrated transportation wheels.

A number of positive aspects help the MISTRAL laser systems from NWL Laser Technology to stand out from other marking lasers. A highly flexible cabin, user software that is simple to use and an extremely reliable laser distinguish the NWL marking systems. Available with laser powers ranging from 8 to 50 Watts and outstanding capabilities in terms of flexibility due to its open architecture it can be easily integrated into new or existing assembly lines. Two different types of laser marking heads are available to accommodate various part orientations, marking applications and available space, Nd:YAG or Nd:YVO4, simply choose the one that best suits your specific conditions. In addition, the power supply units can be supplied in a standard 19" rack mount to fit into a wide variety of industrial cabinets. The MISTRAL has a well designed protective housing and although a Laser Class-l device is a versatile, compact and mobile system with outstanding performance features. Pull the marking cabinet to the forward position and you have an ergonomic seated work station. Or, separate the marking cabinet from the lower supply housing to integrate into your automated assembly line. As well as the many standard features there are many optional components available such as part feeding units or semi automated part supply devices. The small footprint of the MISTRAL lets you easily find a suitable place for your laser marking system and is very portable due to its integrated transportation wheels.

Kaye-Dee Marking Solutions will be unveiling their new NWL laser product range at MEDTEC UK 2009. See us on stand 2010 (Hall 19).

- Contact Information

- Name: Christian Simpson

- Email: info@kayedee.co.uk