8 September 2009

GSI Launches new JK604D pulsed Laser

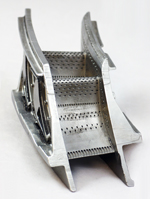

This month GSI Group introduces a new product to its popular range of JK Industrial Lasers. The new JK604D laser has been specifically designed to address percussion drilling and trepanning within the Aerospace and Automotive industry sectors. Typical applications include drilling of cooling holes (effusion) in jet engines and gas turbine components such as nozzle guide vanes, blades and combustor liners.

This month GSI Group introduces a new product to its popular range of JK Industrial Lasers. The new JK604D laser has been specifically designed to address percussion drilling and trepanning within the Aerospace and Automotive industry sectors. Typical applications include drilling of cooling holes (effusion) in jet engines and gas turbine components such as nozzle guide vanes, blades and combustor liners.

GSI has many years of experience in supplying lasers for these applications, with their JK704 Drilling Laser being the industry standard laser of choice in aerospace drilling applications. Building on this experience the JK604D brings the advantages of the field proven technology of new JK Pulsed Laser platform to Aerospace drilling applications.

Both existing operators of the JK704 and new users will recognize the importance of the benefits offered by the new JK604D laser.

Firstly, a beam quality that is consistent over the wide operating range, but has been improved by 30% over the industry benchmark of the JK704LD1, which reduces the focused spot size, whilst increasing the peak power density and depth of focus, leading to a broad processing envelope and ease of application parameter determination.

Secondly, a wide operating envelope, without the need for potentially troublesome variable intra-cavity optics, allows more flexibility in choosing operating parameters and matching them to processing speed variations. Coupled with fast and consistent warm-up characteristics and inherently high stability of the laser, it makes the JK604D an ideal choice for drill-on-the-fly applications, particularly with irregular hole patterns.

Secondly, a wide operating envelope, without the need for potentially troublesome variable intra-cavity optics, allows more flexibility in choosing operating parameters and matching them to processing speed variations. Coupled with fast and consistent warm-up characteristics and inherently high stability of the laser, it makes the JK604D an ideal choice for drill-on-the-fly applications, particularly with irregular hole patterns.

Thirdly, the use of reliable, modular power supply technology from the JK Pulsed Laser Range allows a smaller power supply footprint and the use of the LaserView ™ graphical user interface for complete control and easy, high- speed interfacing to system level controllers.

Providing an optimised peak power of 16kW, the new JK pulsed laser has sufficient energy to percussion drill a wide range of Aerospace components, and has a demonstrated capability for percussion drilling low angle (30° or less) holes in both single crystal turbine blade and typical guide vane alloys in the range of 0.25mm to 0.8mm in less than one second, with low recast layer thickness.

The JK604D; with class leading beam quality enables high quality hole profiles, high intensity laser spot for fast removal rates, separate laser head for closer integration to work area and the ability to produce high speed, high performance drilling to meet demanding and unusual applications. As with all JKTM lasers; the JK604D has been built with enhanced technologies to offer the best overall value, dependability and cost of ownership.

- Contact Information

- Name: Andrea Martin

- Email: amartin@gsig.com