1 October 2009

Rofin Laser Technology ? Fresh Ideas for the Packaging Industry

To many consumers, food packaging is seen as little more than an attractive array of bags, stand up pouches, plastic trays and cartons, designed to entice them to purchase the product. For the manufacturers and retailers however, today’s packaging is the result of extensive research and is a high technology product, designed to extend shelf life and freshness whilst providing unprecedented levels of functionality for the user. Many of the features incorporated in modern packaging, which consumers now take for granted, would not be feasible were it not for the processing capabilities of lasers.

Fig.1: Precise perforations for easy ventilation Designed for longer shelf life of fresh food Fig.1: Precise perforations for easy ventilation Designed for longer shelf life of fresh food |

Keeping produce fresher for longer

Modified Atmosphere packaging (MAP) increases the shelf life of fresh and refrigerated food products. For perishable food in particular, shelf-life has a great influence on its value. The growth in markets such as healthy foods and snacks, has driven the requirement for not only attractive presentation, but extended shelf life for products such as organic fruit, vegetables, nuts, dried fruit and cereals. The freshness of these products is largely determined by air-ventilation and the preservation of humidity within the packaging. To achieve this requires a series of precise and consistent perforations (Fig.1) which are produced using a laser. An additional requirement has also arisen for multi-chamber trays used for multi-component snacks. For these products each chamber requires perforating differently, to optimise the storage life of the ingredients within that particular chamber.

Fig.2: StarPerfo Advanced with web movement compensation - WMC for identical hole size and shape Fig.2: StarPerfo Advanced with web movement compensation - WMC for identical hole size and shape |

These perforations need to be generated “on the fly” as the packaging material moves at high speed. When a laser pulse hits fast moving material, the resultant quality of the hole may not be as required. If pulse duration and web speed exceed certain values, the holes can become visibly oval.

Historically, in many cases, material that had been produced at high speed may not have been of the accuracy required to allow the specified air exchange and may therefore have been deemed inefficient at best and at worst, unusable. To eliminate these problems and match web speeds which can reach 500m per minute, Rofin developed the StarPerfo Advanced (Fig.2). Using Rofin’s Web Movement Compensation System (WMC), StarPerfo Advanced has the capability to control and optimise the perforation hole dimensions, further enhancing the shelf life of fresh food products. This means less waste, lower costs and ultimately more attractive pricing for the customer.

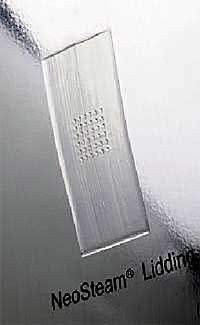

Fig.3: Laser perforated array for easy ventilation of micro wave food packaging Fig.3: Laser perforated array for easy ventilation of micro wave food packaging |

Lasers let off steam for microwave food

In today’s fast moving world, snack foods, ready meals and convenience foods continue to grow in popularity. Many of these foods are prepared in the microwave and prior to cooking, consumers are usually required to puncture the covering film to allow steam to escape. NeoSteam® packaging, developed by Mondi Consumer Flexibles, ensures that microwave food retains its vitamins and minerals and is also very easy to prepare. This leading edge packaging concept incorporates a pressure regulation valve generated by laser perforation using a Rofin StarShape Laser and eliminating the need to manually puncture the film before cooking. In addition, the precise nature of laser processing enables the valve to be configured to match the individual steam properties of the particular product (Fig.3).

Making light work of opening

The consumer’s product experience can be adversely influenced if the packaging is difficult to open. If the opening process requires too much initial force, this can result in spillages or even minor injuries. Manufacturers must also consider the needs of the ever increasing elderly population where ease and consistency of opening are essential attributes. Difficult to open packaging is often the result of poor or inconsistent quality of mechanically created opening lines. Rofin StarScribe and StarPerfo lasers on the other hand, offer a reliable and consistent non-contact solution to a wide range of scribing and perforation applications.

Fig.4: Easy opening features generated using Rofin Laser Fig.4: Easy opening features generated using Rofin Laser |

Also known as selective weakening, (Fig.4) the laser is set to “select” a particular film layer(s) generating the easy open tear lines whilst leaving the other layers, which are required to protect the product from light and humidity, intact. Almost all packaging foils are so-called multilayered structures consisting of several layers. Different layers usually have different functions. PET for example makes for stiffness and aroma conservation, PE for sealing and tear resistance, PP for water vapour tightness and aluminium for the general light protection. With easy opening, the supporting layer is selectively weakened without affecting other functionalities.

With today’s consumers expecting continuous improvements on freshness, quality and greater convenience, packaging manufacturers will seek to develop new packaging materials and concepts to meet these demands, aided by Rofin’s application experts and comprehensive range of laser systems.

Rofin offers a complete range of lasers including CO2, Vanadate and Fibre Lasers. Rofin also provides solutions for laser marking, cutting and welding applications.

- Contact Information

- Name: Dave MacLellan

- Email: sales@rofin-baasel.co.uk