9 November 2009

Rofin Laser System Rolls Out Flexible Photovoltaic Products

As the demand for clean energy intensifies, the use of photovoltaics as a source of renewable energy will undoubtably increase as manufacturing and production costs reduce and photovoltaic efficiencies improve. Although traditional solar panels are becoming commonplace they can be bulky and are often installed in a fixed position.

As the demand for clean energy intensifies, the use of photovoltaics as a source of renewable energy will undoubtably increase as manufacturing and production costs reduce and photovoltaic efficiencies improve. Although traditional solar panels are becoming commonplace they can be bulky and are often installed in a fixed position.

Flexible photovoltaic products can be used in the same way as traditional solar panels, however this technology is not only flexible in its construction, but more easliy adapted to a broader range of applications. This type of solar panel is highly portable and can therefore make solar energy more readly available in a greater range of environments.

Lasers already play a key part in the manufacture of silicone and thin film solar cells, and the ongoing development of products such as flexible photovoltaic materials has seen the use of lasers expand even further within the industry.

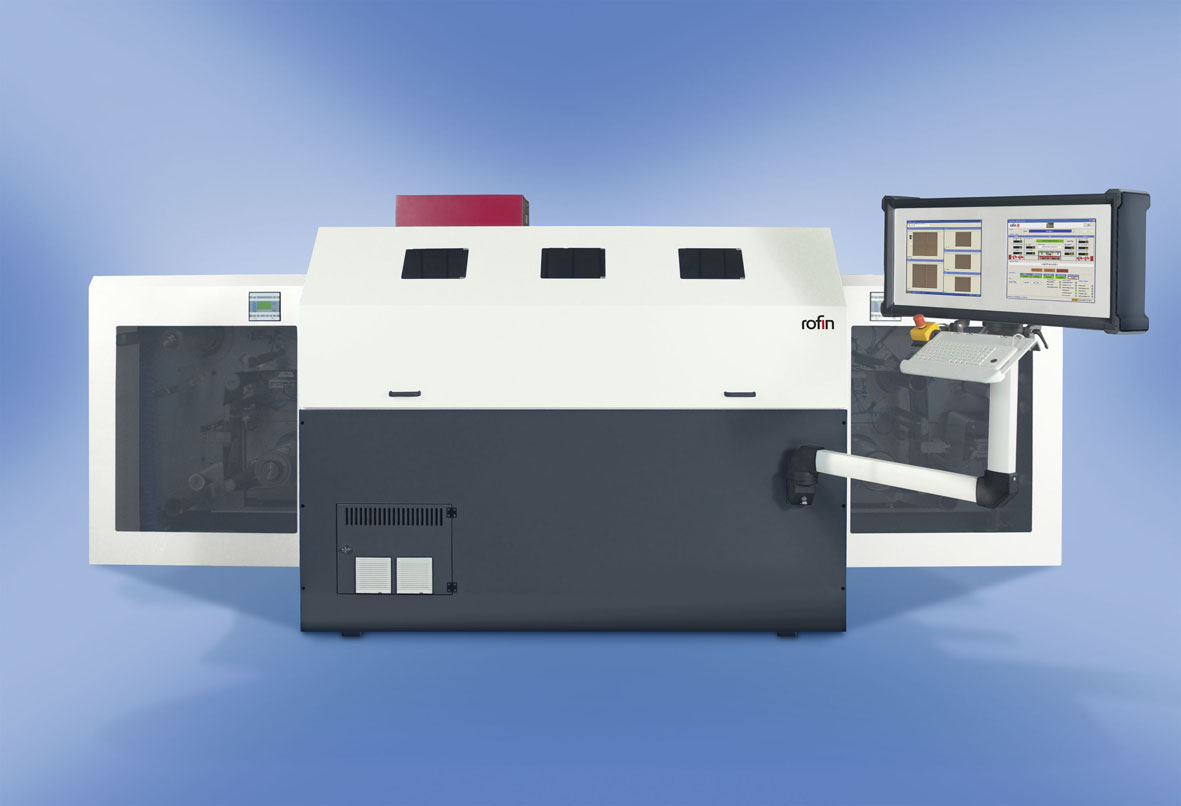

Rofin is well established as a major player within the photovoltaic industry, with over 10 years experience and offering a comprehensive range of lasers which include CO2, Nd:YAG, Nd:Vanadate, Disc, Fibre and Diode in Multi/Monomode, Q-switched and frequency-multiplied formats. Now, with over 1,000 lasers installed within the industry worldwide, the extensive applications experience gained by the company has been harnessed in a new turnkey reel to reel system targeted at the production of flexible photovoltaic products.

This new reel to reel system has been designed to incorporate multiple laser sources which can be used to perform several different processing tasks on Si, µSi, GIGS and organic cells, all within a single machine. Built upon a substantial granite base, the system incorporates high speed, high precision motorised axes to drive vibration proof optics when the system is being used used in the step and repeat mode.

For on-the-fly applications, beam positioning is achieved using fast and precise galvo scanning heads. A fully integrated vision system allows precise alignment with fiducials and also enables automated inspection tasks to be carried out within the machine.

New Laser Source for Thin Film Scribing

.jpg) Photovaltiac manufacturing requires laser sources which have been optimised for the particular process to be performed. Rofin’s new PowerLine SL PV series has been specifically developed for use within the automation and production systems used by the industry.

Photovaltiac manufacturing requires laser sources which have been optimised for the particular process to be performed. Rofin’s new PowerLine SL PV series has been specifically developed for use within the automation and production systems used by the industry.

Typical applications for this new laser include, scribing TCO/ITO/AZO layers on flexible substrates of the type which can be produced within the new, self contained, Rofin production system. The PowerLine SL PV is available in two wavelengths 1064nm and 532nm and its compact size means that it is ideally suited to machine integration where one laser per scribe head is required. For applications where beam splitting is appropriate, the higher output power of the PowerLine E series laser will support 2 or 4 scribing heads from the single laser source.

This latest reel to reel production system, coupled with the new PowerLine SL PV series laser, is a clear demonstration of Rofin’s commitment to providing not just laser sources, but complete solutions for the developing flexible photovoltaic industry. Rofin’s extensive industry experience and unrivaled applications knowledge will ensure that the company remains at the forefront of this important part of the renewable energy market.

- Contact Information

- Name: Dave MacLellan

- Email: sales@rofin-baasel.co.uk