2 February 2010

Additive Layer Manufacturing Reaches for the Sky

Additive layer manufacturing for direct part production continues to grow and is fast becoming a significant part of the overall ALM industry. The many benefits of this process have seen the technology embraced by a number of manufacturing sectors, not least the aerospace industry. The ability to produce components in a wide range of materials including hot work steels, stainless steel, cobalt chromes, inconel plus titanium and aluminium alloys, presents the aerospace industry with immense potential for direct part production using ALM.

Additive layer manufacturing for direct part production continues to grow and is fast becoming a significant part of the overall ALM industry. The many benefits of this process have seen the technology embraced by a number of manufacturing sectors, not least the aerospace industry. The ability to produce components in a wide range of materials including hot work steels, stainless steel, cobalt chromes, inconel plus titanium and aluminium alloys, presents the aerospace industry with immense potential for direct part production using ALM.

Additive Layer Manufacturing has already proven its capability to produce small and medium sized aerospace components, and having realised the potential of the process, aerospace manufacturers are now seeking to produce larger and more complex parts.

Birmingham based Material Solutions operates an ALM applications development centre with a particular focus on the aerospace sector. Carl Brancher of Material Solutions explains “Additive Layer Manufacturing (ALM) in high performance metals is well suited for complex thin walled structures in gas turbines. However as a new technology it is not yet well understood or validated by potential users and like all manufacturing processes, to get the best from metal ALM requires the designer to understand the process capabilities and materials mechanical properties. Materials Solutions is bridging this gap by providing manufactured parts, consulting (principally to the aerospace market) and working with equipment and materials vendors to develop the technology for mass production”

The collaboration between Material Solutions and their industry clients has so far led to the production of a wide range of components over the last 3 years. This programme has now reached the limit of component size which can be produced using the existing Material Solutions ALM systems. With the continuing pressure from aerospace manufacturers to develop the capability to produce larger parts, Material Solutions turned to Concept Laser GmbH to explore the potential for building larger components using Concept Laser’s M3 linear system.

Linear drives allow large build volumes

The fundamental principles of the M3 linear make it quite unique in the world of additive layer manufacturing. Unlike other machines the M3 linear does not have fixed optics but a combination of galvo scanning mirrors and linear direct drives to move the scanning head. Already used to build larger volume components, the M3 linear has all of the pre-requisites for up-scaling to enable production of the types of components envisaged by the aerospace industry. It is not only the physical attributes of the system which lend themselves to production of large components but the process control and laser scanning strategy already developed by Concept Laser GmbH, which will eliminate the potential pitfalls of accuracy errors on large components.

The fundamental principles of the M3 linear make it quite unique in the world of additive layer manufacturing. Unlike other machines the M3 linear does not have fixed optics but a combination of galvo scanning mirrors and linear direct drives to move the scanning head. Already used to build larger volume components, the M3 linear has all of the pre-requisites for up-scaling to enable production of the types of components envisaged by the aerospace industry. It is not only the physical attributes of the system which lend themselves to production of large components but the process control and laser scanning strategy already developed by Concept Laser GmbH, which will eliminate the potential pitfalls of accuracy errors on large components.

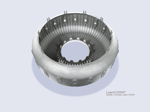

Having established the potential of the M3 linear machine, Material Solutions set out to design a test component which would qualify certain build criteria and which could also be used to educate and inform aerospace designers of “Additive Friendly” design features and techniques. These include; reducing supports and using larger flowing radii to assist in reducing the time to build and subsequently, component production and finishing costs. The test part incorporates many features such as small diameter holes, threaded features, thin rib sections and areas of thick material section all typically found in aerospace components. The greatest challenges for Concept Laser GmbH were that a component of this size had never before been built and added to this the part was required in an unexpectedly short timescale.

The finished component demonstrates the current capabilities of the technology in terms of size (300 mm diameter), accuracy and surface finish. Whilst this part does not yet satisfy the ultimate demands of aerospace manufacturers it clearly confirms the capabilities of the process, the scalable potential of Concept Laser’s M3 linear machine and the sound base which Concept Laser have for further development of the M3 linear for large aerospace components.

There are also practical aspects to be considered when building large parts. Larger volume components require greater volumes of powder and hence a robust and stable platform to accommodate the weight. Having then built a large volume, and potentially very heavy component, safe and easy removal is essential The M3 linear machine is built around a substantial fabricated framework and already incorporates a removable build module enabling the module and component to be easily positioned under an overhead crane if required.

The success of this exercise and the current collaboration between Material Solutions and Concept Laser GmbH will be used to define the future strategies and technical milestones which will eventually see parts manufactured by ALM techniques leave the laboratory and take to the air.

- Contact Information

- Name: Colin Cater

- Email: c.cater@estechnology.co.uk

- Website: www.estechnology.co.uk