10 August 2010

Cutting Foil-Coated Paperboard Packaging

Paperboard is widely used for packaging and cartoning food products to provide rigidity and mechanical support. Laminating an ultra-thin aluminium foil to the paperboard adds oxygen and moisture resistance that serves to prevent spoilage of food. In the aseptic packaging industry, the final touch is an inner layer of polyethylene that makes the package liquid-tight. This combination of materials combined with UHT (ultra-high temperature) sterilisation allows milk and juice products to be shipped and stored without requiring refrigeration until opened by the consumer.

Paperboard is widely used for packaging and cartoning food products to provide rigidity and mechanical support. Laminating an ultra-thin aluminium foil to the paperboard adds oxygen and moisture resistance that serves to prevent spoilage of food. In the aseptic packaging industry, the final touch is an inner layer of polyethylene that makes the package liquid-tight. This combination of materials combined with UHT (ultra-high temperature) sterilisation allows milk and juice products to be shipped and stored without requiring refrigeration until opened by the consumer.

This application trial shows the feasibility of laser cutting 102 mm (4.0”) diameter foil-coated paperboard tubes to length. Because the composite tubes have a wall thickness of 1 mm (0.04”), the cutting head was set up with a 63.5 mm (2.5”) positive-meniscus focusing lens that provides a 100-micron (0.004”) spot with a 1.8 mm (0.07”) depth of field. A 2.8 bar (40 PSI) air assist, delivered coaxially with the beam, was used during the cutting process to remove vaporised material from the cut area.

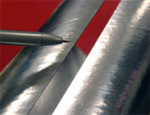

Using a Firestar f201 laser at a power level of 200 watts, the foil-coated paperboard tubes were cut at a rate of 10.2 metres per minute (400 inches/minute). For a 102 mm (4.0”) diameter tube, this equates to a cycle time of 1.9 seconds to cut around the 320 mm (12.6”) circumference. Notice that the cut paperboard edge exhibits an exceptionally clean cut with very slight discoloration.

- Contact Information

- Name: Gary Broadhead

- Email: garyb@laserlines.co.uk

- Website: www.laserlines.co.uk