13 August 2010

Update from University of Nottingham laser group

Over the last year four students have completed their PhD’s in laser processing from the University of Nottingham laser group. Namely, Nur Hussein (Direct metal deposition of Waspaloy), Said-Omar Al-Mashikhi (High brightness fibre laser cutting), Jongkol Iammi (Fibre laser welding of AISI 304 and Ti-6Al-4V), Alexis Medrano Tellez (Fibre laser metal deposition with wire: parameter study and temperature control). The group is currently recovering (!) and continuing research at all levels in areas of material processing cutting, welding, deposition and surface treatment.

The group has also just been awarded an iNET grant for research into laser pre-conditioning and repair of rails in conjunction with industry.

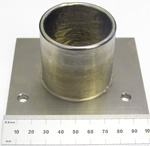

The prettiest parts from the group (besides some nice micro scaffolds) are as a result of the deposition work. This is a titanium cylinder that took 15 minutes to build. This particular cylinder was built using a fibre laser at a power of 1-1.3kW. Active temperature control was used to keep the temperature in the deposition zone at 1850°C.

A similar technique was used to build the larger component which is shown before and after machining. Work in this area of deposition has been ongoing since 2001 including work for industry and various publications.

- Contact Information

- Name: Janet Folkes

- Email: janet.folkes@nottingham.ac.uk

- Website: www.nottingham.ac.uk/school4m/