5 January 2011

An economical solution for electric car manufacturing

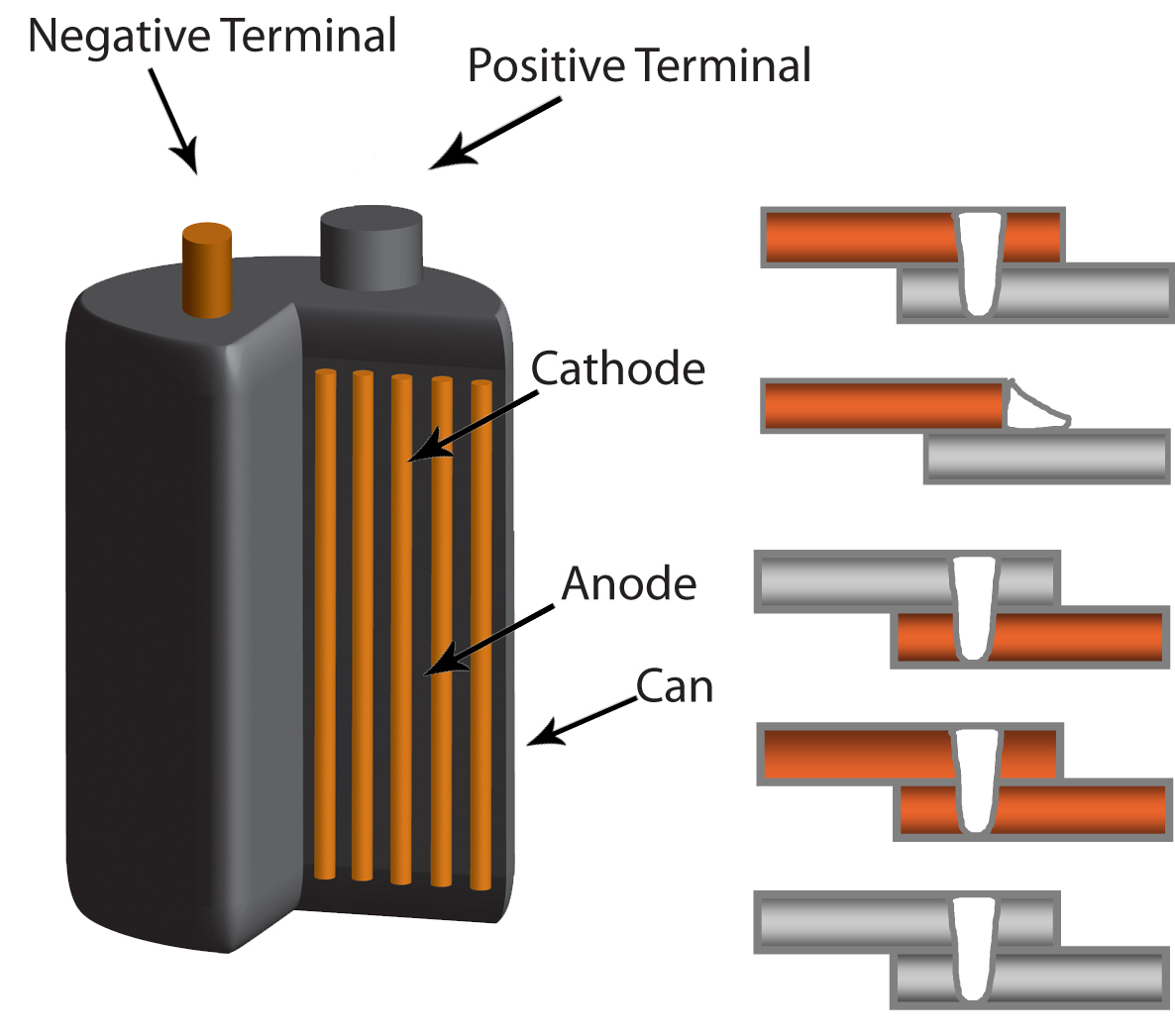

We all know how important it is to be eco-friendly, which is why more of us are taking action and opting for electric vehicles. These cars are powered by lithium ion batteries which are smaller and lighter than traditional vehicle batteries. However, EVB’s are constructed from a combination of materials, posing a particular challenge when welding.

We all know how important it is to be eco-friendly, which is why more of us are taking action and opting for electric vehicles. These cars are powered by lithium ion batteries which are smaller and lighter than traditional vehicle batteries. However, EVB’s are constructed from a combination of materials, posing a particular challenge when welding.

Fortunately, tests conducted by JK™ Lasers have proven that their portfolio of fiber lasers are capable of welding together the aluminium and copper found within these components.

The trials, conducted using a single mode JK™ fiber laser, demonstrated that the laser’s high beam quality and brightness, can achieve consistent, defect free joints at higher speeds – features which are crucial for most battery manufacturers. The laser’s small spot size also produced narrow welds, which minimised the formation of brittle intermetallics.

In addition to the physical properties that the results show a fiber laser can attain, the compact footprint and low power consumption of these lasers ensure that the manufacturing process is just as economical as the resulting vehicle.

- Contact Information

- Name: Mark Greenwood

- Email: mgreenwood@gsig.com

- Website: www.gsiglasers.com