25 July 2012

Laser engraving - how hard can it be?

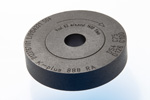

How do you engrave a diamond engraving wheel?

How do you engrave a diamond engraving wheel?

Some materials are so hard that it is difficult to imagine being able to engrave detailed information such as type, serial numbers and logos using any contact method. Modern pulsed fibre lasers however are capable of ablating any material that absorbs at the near infrared wavelength - at which these lasers operate.

This grinding wheel has been laser engraved using a Rofin fibre laser, which is also ideally suited to engraving other difficult materials such as ceramics, carbides and polycrystalline diamond.

The laser beam is deflected under computer control and each pulse of energy, lasting around a tenth of a billionth of a second, is sufficient to vaporise a tiny amount of material form the surface of the part being processed.

In this example, the results obtained by laser engraving are clear to see. Rofin’s fibre lasers produce high quality, concise text and graphics that are easily human readable and which will survive the rigors of a production environment.

It is not only marking and engraving applications on difficult materials where the laser excels. Rofin Lasers are used to mark virtually all metals and plastics, plus various other materials, with high contrast. Different marking methods and laser sources are used, to achieve the desired results on every type of material.

Rofin offers a complete product line-up, optimised for laser marking: laser sources, laser markers, all-in-one laser marking systems and customized marking solutions. In order to provide the perfect match for specific application requirements, laser sources are available in different power ranges and wavelengths of 1064, 532 and 355 nm.

Rofin marking lasers are recognised for their superior beam quality and excellent mechanical and optical quality ensuring sustained, precise marking results and reliable operation in demanding industrial environments.

- Contact Information

- Name: Mike Batchelor

- Email: sales@rofin-baasel.co.uk

- Website: www.rofin.co.uk