15 March 2013

New process optic options for laser welding

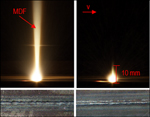

During laser welding, particles in the metal vapour plume can cause a deviation of the laser beam. They also absorb laser power. Both can lead to inconsistent welding depth and irregular seams. It is to suppress the plume and optimise application results that TRUMPF has developed a special coaxial nozzle.

During laser welding, particles in the metal vapour plume can cause a deviation of the laser beam. They also absorb laser power. Both can lead to inconsistent welding depth and irregular seams. It is to suppress the plume and optimise application results that TRUMPF has developed a special coaxial nozzle.

In addition to assuring welding depth and constant surface quality, the new nozzle ensures higher precision and optimised use of laser power. Operating costs are also reduced through the increased service life of the protection glass.

Trial results are impressive. The new nozzle prevents up to 22% less original laser power loss and up to 40% greater welding depth, dependant on process gas and speed. It also ensures a reduction in weld spatter on material surfaces.

Also new is the TRUMPF cassette module, another laser welding option for manufacturers wishing to safeguard their TRUMPF OEM laser or TruLaser Robot system. This unit is designed to increase the lifetime of both the optics and the protection glass. It also reduces the risk of contamination by introducing an air flow to blow away any debris from optics when changing the protection glass.

- Contact Information

- Name: Gerry Jones

- Email: g.jones@uk.trumpf.com

- Website: www.uk.trumpf.com