28 January 2014

New Software Identifies Laser-Profiled Parts

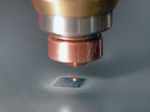

The latest version of Bystronic's CNC software controlling its laser profiling machines enables labelling of cut parts, ensuring that bending is carried out correctly afterwards. PartID is a new function within BySoft 7 that automatically laser-engraves cut parts with an identification code.

The latest version of Bystronic's CNC software controlling its laser profiling machines enables labelling of cut parts, ensuring that bending is carried out correctly afterwards. PartID is a new function within BySoft 7 that automatically laser-engraves cut parts with an identification code.

When the component is transferred to a Bystronic pressbrake, the code is scanned to ensure that the correct bending program is loaded. The risk of human error is lowered and mix-ups with similar parts eliminated, raising process reliability, saving time and reducing scrap.

PartID within Bysoft 7 is applicable to all of Bystronic's laser cutting machines, both CO2 and fibre. Subsequent processing machines must be fitted with ByVision Bending, the Swiss manufacturer's graphical user interface for pressbrakes, and an additional scanning unit. For customers with and without Bystronic bending machines, the code can be useful to recognise the part by scanning with a smart phone or similar device.

Parts removal in Plant Manager

Plant Manager, another BySoft 7module that plans and monitors laser (and waterjet) cutting processes, has also gained a new feature, called Parts Removal. It provides visual support to the operator when unloading cut parts at the shuttle table.

All of the parts that belong to a customer order can be colour-coded on the cutting plan and are clearly distinguishable from parts required for other orders. First and last cut parts can be labelled so that the machine operator recognises when an order begins and when it is completed. After the finished parts have been unloaded, the operator has the option of registering the status on the control screen to facilitate traceability.

- Contact Information

- Name: David Larcombe

- Email: david.larcombe@bystronic.com

- Website: www.bystronic.com