15 May 2014

Spritzguss + Formenbau Bergmann purchases first metal additive manufacturing system from EOS

EOSINT M 280 metal system enables a 20% reduction in injection moulding cycle times

Spritzguss + Formenbau Bergmann, based in Northern Germany, has purchased its first metal additive manufacturing (AM) system, an EOSINT M 280 from EOS, and has also become a service provider to the supplier. Bergmann designs and produces injection mould tools and produces high grade plastic components using more than 70 injection moulding machines.

Spritzguss + Formenbau Bergmann, based in Northern Germany, has purchased its first metal additive manufacturing (AM) system, an EOSINT M 280 from EOS, and has also become a service provider to the supplier. Bergmann designs and produces injection mould tools and produces high grade plastic components using more than 70 injection moulding machines.

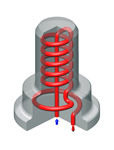

The purchase of the EOSINT M 280 enables the company to produce tool inserts, such as cores and slides, as well as prototypes directly from metal. The system is based on the DMLS (direct metal laser sintering) process, which builds components layer by layer based on 3D CAD data. Constant monitoring maximises the quality and repeatability of components.

Complex geometries can be achieved, such as freeform surfaces, fins and cooling channels. In particular, it is possible to create conformal cooling channels using DMLS, which reduce moulding cycle times and improve the quality of the plastic components produced. The material most commonly employed in tool construction is EOS MaragingSteel MS1.

Augustin Niavas, business development manager for tooling at EOS points out: “We are pleased to have found a strong and highly professional partner for injection moulding, one which has many years of experience with conventional technologies but which is at the same time open to innovative technologies.

“The fact that Bergmann has chosen EOS technology reflects the level of maturity that additive manufacturing has now attained. Together, we are able to cover the entire process chain, from the engineering design stage of the tool to the finished plastic component.

“From this position we will continue to jointly support customer projects in the future and develop the market for additive manufacturing in tool construction.“

André Gerbert, assistant to the senior management at Spritzguss + Formenbau Bergmann adds: “Right from the start we were convinced about the benefits of the EOS additive manufacturing process. Not only can we employ the new metal system for tool making on the premises but we can now also perform contract work for our customers, based on this new manufacturing technique.

“It means that we are already able to achieve considerable reductions of up to 20 percent in cycle times. Moreover, as additive manufacturing enables conformal cooling of tool cores, we can produce a tool that is 50 per cent better in terms of functionality.

“It should be noted that half of the tool cores that we are now able to produce using the EOS system could not be manufactured using conventional methods.“

- Contact Information

- Name: Stuart Jackson

- Email: stuart.jackson@eos.info

- Website: www.eos.info