11 May 2015

Two-axis gear-drive gimbal is both economical and accurate

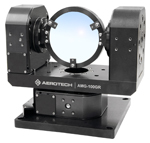

- Economical, high-accuracy, two-axis gimbal design

- Travels from 90 degrees to continuous rotation

- Circular (100 to 300 mm) and custom cells

- Front surface reflecting and centered cell options

- Direct encoder option for increased accuracy/repeatability

- Servo and stepper motors available

AMG-GR gear-driven motorised gimbals provide economical, high-accuracy elevation-over-azimuth positioning. The AMG-GR is available in a variety of standard travel ranges in both azimuth and elevation to fit any application. Due to the flexibility of the design, customized travels are easily accommodated. A variety of accuracy grades, motor types, and cell designs make this the ideal solution for applications ranging from sensor calibration to laser beam steering.

AMG-GR gear-driven motorised gimbals provide economical, high-accuracy elevation-over-azimuth positioning. The AMG-GR is available in a variety of standard travel ranges in both azimuth and elevation to fit any application. Due to the flexibility of the design, customized travels are easily accommodated. A variety of accuracy grades, motor types, and cell designs make this the ideal solution for applications ranging from sensor calibration to laser beam steering.

Cell Design Versatility

The AMG-GR standard circular cells range from 100 mm to 300 mm in diameter. Cell mounting options include a centered (balanced) cell or a front-surface reflection option where the front of the optic is located on the axes of rotation. Special configurations are available to accommodate non-circular optics, cameras, sensors, and round optics larger than 300 mm in diameter. The modular design permits each gimbal mirror cell to be easily modified or replaced with different shaped cells to accommodate sensors or other asymmetrically-shaped payloads.

Flexible Options

The AMG-GR can be outfitted with brushless servo or stepper motors. A full range of matching drives and controls are available for a complete single-source solution. For applications that require high accuracy and repeatability, a direct-encoder mounted to the cell and yoke is available. Vacuum-compatible versions are also offered.

- Contact Information

- Name: Cliff Jolliffe

- Email: cjolliffe@aerotech.co.uk

- Website: www.aerotech.com