8 June 2015

Bayerisches Laserzentrum and ROFIN showcase ultrashort pulse laser application with highly dynamic massless beam deflection

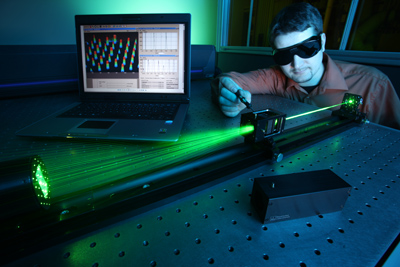

Cutting-edge systems technology with ultrafast beam deflection allows for new micro material processing applications with unrivalled speed. At LASER World of Photonics 2015 the Bayerische Laserzentrum (blz) demonstrates this process with an ultrashort pulsed scribing process for organic solar cells manufacturing.

Cutting-edge systems technology with ultrafast beam deflection allows for new micro material processing applications with unrivalled speed. At LASER World of Photonics 2015 the Bayerische Laserzentrum (blz) demonstrates this process with an ultrashort pulsed scribing process for organic solar cells manufacturing.

blz showcases a manufacturing cell with ROFIN’s ultrashort pulse laser source StarFemto and three different beam guidance technologies at its booth 524 in hall A2. Visitors are welcome to watch liquid crystal spatial light modulation (SLM), acousto-optic modulation and conventional galvo scanner deflection in direct comparison. The demonstration will illustrate the significant increase in processing speed which is a factor of 5 to 10 times greater.

Powerful laser sources require new highly dynamic beam guidance

Efficient mass production requires highly productive and cost-efficient manufacturing processes. This is where cutting-edge systems technology offers substantial benefits.

To take full advantage of new and powerful high repetition, single pulses have to be selected and distributed over the workpiece. ROFIN’s StarFemto laser source, with 20 W average power and up to 2 MHz pulse frequency, meets this critical demand. This allows for dramatically higher throughput rates and reduces the risk of unwanted heat accumulation due to fast repeating pulses in one spot. blz shows two cutting-edge, highly dynamic beam guidance technologies. Modulating phase and/or amplitude of light waves with liquid crystal SLMs allows for splitting the laser beam or reshaping its intensity profile. With acousto-optic modulators on the other hand super fast beam deflection can be realised.

Innovative laser systems technology making the leap to industrial manufacturing

New ultrafast micro material processing technologies will have great impact on the efficiency and throughput of future laser material processing applications. blz integrates innovative beam guiding technologies with laser sources like ROFIN’s StarFemto and specialized control software to new industrial solutions.

Image: Fuchs/blz

- Contact Information

- Name: Andy May

- Email: a.may@rofin-baasel.co.uk

- Website: www.rofin.co.uk