3 February 2016

TWI and Metalysis demonstrate 3D-printed tantalum biomedical implants

Hip and spinal joint replacement patients could soon be receiving individualised, metal 3D-printed implants, thanks to a pioneering project from an industry partnership.

Hip and spinal joint replacement patients could soon be receiving individualised, metal 3D-printed implants, thanks to a pioneering project from an industry partnership.

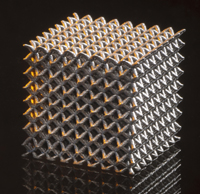

Metalysis, the metal powder technology company, has collaborated with TWI, the leading material joining and technology engineering company, to demonstrate the feasibility of its tantalum powder in metal additive layer manufacturing for biomedical applications such as patient-bespoke hip joints. The study successfully produced both uniform and randomised tantalum lattice structures that are bio-inert, replicate the structural stiffness of bone and allow for extensive integration with bone cells, so that the new joint is readily accepted by the body.

Metalysis has developed a process that produces metal powders directly from their respective oxides in just a single step, drastically lowering the environmental impact of its manufacture. The innovative process is not only cost-competitive, but also produces perfectly spherical metal powders of uniform size so that when used in metal additive manufacturing, the end product is structurally consistent and allows for an improvement on the as-built surface finish. This study has proved that the properties (i.e. durability and inertness) of this highly versatile metal are retained through the production process. This is due to the quality of Metalysis’ powders which allows the 3D printer to lay down the metal, forming a lattice structure, with consistent strength and density.

To date, most additive manufacturing technologies have focused on the use of commodity plastics, because powdered metals, until now, have proved too expensive to be widely used for this process. Now, Metalysis’ high-quality metal powder, combined with TWI’s expertise, has demonstrated the significant potential of creating lattice structures using a specific metal additive manufacturing technique – selective laser melting (SLM) – for use in hip joints, implants and other new biomedical products that will both benefit patient wellbeing and bring cost savings to the wider market. Research specialist TWI has a history of bringing advances to the medical industry, and this study shows that Metalysis’ metals can be used to manufacture prototypes of the highest levels of quality by exploiting SLM additive manufacturing technology.

Metalysis is spearheading a revolution in the production of high-quality metals including tantalum and titanium. Its patented process replaces the outdated, extremely expensive and highly toxic Kroll or Hunter process which has been used for the past 70 years. Up until now, the inefficiency and expense of this process has made titanium and tantalum prohibitively expensive. Since the launch of its commercial plant in 2015, Metalysis has been supplying tantalum powder to its clients globally, working in collaboration with LPW Technology to serve its additive manufacturing customers.

Richard Pargeter, a technology fellow at TWI, commented: ‘We have already seen the great success Metalysis has had printing automotive parts. Our analysis suggests these metals are incredibly versatile and highly suited to the medical industry. Metal 3D-printed hip replacements could be a huge step forward, allowing patients to have a tailor-made joint by scanning their other hip and matching it with a metal 3D-printed replacement, rather than being restricted to the choice of standard sizes now available.’

Dion Vaughan, chief executive of Metalysis, said: ‘It is tremendous to be partnering with TWI, a company that has so much knowledge in the manufacturing and medical industries. TWI has great expertise, particularly in the use of lasers in additive manufacturing, which we hope will help to bring individual joint replacements into the mainstream of mass manufacture.’

Image: example of the lattice structures created under the project

- Contact Information

- Name: Jon Blackburn

- Email: jon.blackburn@twi.co.uk

- Website: www.twi-global.com