16 November 2016

VISI's design role in head injury prosthesis

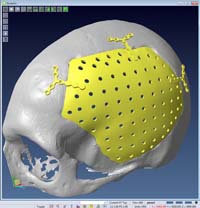

Doctors and engineers in Mexico used VISI software to design a 3D printed titanium cranial prosthesis for a patient who had been shot in the head. The prosthesis was designed using the VISI CAD/CAM suite from Vero Software, and undertaken free of charge by designers and engineers from Vero’s Mexican reseller, VISI Series Mexico.

Doctors and engineers in Mexico used VISI software to design a 3D printed titanium cranial prosthesis for a patient who had been shot in the head. The prosthesis was designed using the VISI CAD/CAM suite from Vero Software, and undertaken free of charge by designers and engineers from Vero’s Mexican reseller, VISI Series Mexico.

The original stereolithography (STL) file of the entire head was provided by the medical team and was produced by a CT/MRI scanner. The STL file was used to 3D print an internal plastic prototype model to analyse the shape of the hole. Working with the doctors, the prototype model was reworked to create a more uniform hole with no fragments. Once happy with the topology of the skull, the prototype model was scanned and imported into the VISI CAD application.

From there, a network of curves was taken from the good side of the skull and mirrored onto the left side to cover the aperture. Then a surface model of the prosthesis was created and doctors were again consulted to help determine the ideal fixing structure and screw locations, and to ensure that the model conformed to the needs and complexities of cranial anatomy. At this point, a plastic prosthesis was printed for assembly to the head prototype to check for alignment and fitting. With a design finalised, the prosthesis was sent to the USA for printing on EOS's EOSINT M280 DMLS machine.

- Contact Information

- Name: Marc Freebrey

- Email: marc.freebrey@verosoftware.com

- Website: www.verosoftware.com