27 January 2017

RAYLASE Provides Solutions with New AM-MODULE for Manufacturers

The new Additive Manufacturing module (AM-MODULE) from RAYLASE offers a universal solution for manufacturers of 3D printing systems. Up to four AM-MODULEs can be operated simultaneously over one build area to accelerate the manufacturing process and create production redundancy.

The new Additive Manufacturing module (AM-MODULE) from RAYLASE offers a universal solution for manufacturers of 3D printing systems. Up to four AM-MODULEs can be operated simultaneously over one build area to accelerate the manufacturing process and create production redundancy.

This manufacturing method, (often referred to as 3D printing) a thin layer of powdered raw material (such as metal) is first spread over a working field or build area. Then a high power laser beam scans rapidly over the powder following a precisely defined path melding it together. After multiple layers are deposited a three-dimensional object gradually emerges.

This process depends on accurate control of the laser source, as well as deflection and focusing of the laser beam. The AM-MODULE from RAYLASE takes this process to a higher level and is based on the SUPERSCAN IV and SUPERSCAN V laser deflection units developed by RAYLASE with ultra-light mirrors, and powerful galvanometers with 100% digital control, enabling exceptionally dynamic beam guidance and extremely high accelerations. The absolute repetition accuracy in the high-performance version is 2.96 µm.

During the sintering process, the focal length for the laser beam changes within the working field. However, the optical elements in the linear translator module ensure precise focusing of the laser beam at all times. They enable dynamic adjustment of spot size and guarantee homogeneous light densities within the spot.

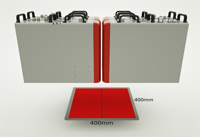

A single AM-MODULE alone can process a build area of up to 500 mm x 500 mm. Thanks to the high degree of working accuracy, up to four AM-MODULEs can be run simultaneously either resulting in a total combined build area of up to 800 mm x 800 mm or by making the manufacturing process up to four times faster. With a maximum laser power of 3 kW, the AM-MODULE can also be used in the area of overlay welding or direct energy deposition.

The AM-MODULE can also be enhanced with an optional sensor module, containing cameras continuously monitor and document the process and component quality with resolutions of up to 15 µm. In addition, they enable ongoing calibration of laser beam guidance over the working field to optimise repetition accuracy.

Alternatively, broadband detecting sensors such as photo diodes and pyrometers for measuring light intensity or temperature can be easily integrated.

The new AM-MODULE from RAYLASE therefore represents a universal yet cost-efficient solution for a range of applications in the area of additive manufacturing. Thanks to an extensive functional scope, a wide range of compatible accessories and the expert support provided by the applications engineers at RAYLASE, the AM-MODULE can be quickly and efficiently integrated as the centerpiece of powerful systems for additive manufacturing.

Product Video: https://youtu.be/cRQl-MgslLQ

- Contact Information

- Name: Harnesh Singh

- Email: h.singh@raylase.de

- Website: www.raylase.de/home/