28 March 2017

SCANLAB's 'Plug & Play' fibre connection for Scan Systems

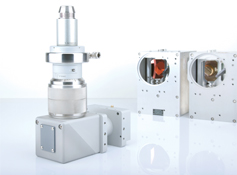

SCANLAB GmbH, the OEM manufacturer of scan solutions, introduces the new collimation module, for reliable connection of fibre-coupled lasers. This industrial-strength fibre coupler helps transform scan heads into a system that can be easily integrated in laser processing machines. The combination with disk or fibre lasers (particularly lasers of higher power classes up to 5 kW), of welding and cutting applications, can be cost-effective– e.g. in auto manufacturing and metal processing

Productivity, quality and cost requirements compel enterprises across all industrial sectors to continually examine and optimise their fabrication processes. In some cases, a carefully conceived system approach can achieve considerable cost reductions. SCANLAB's new collimation module transforms its larger-aperture scan systems – typically 30 mm – into flexible, combinable 2D scan solutions for welding and cutting processes. Compared to an integrated 3-axis system fibre laser based processing systems are substantially lower in cost.

Intelligently Designed to Fulfill Industrial Requirements

The new module's industrial suitability is underscored by a robust fibre-coupler housing with water-cooled stainless steel entrance aperture, as well as a replaceable window protecting the collimation optic. Additionally, the collimation optic is manually adjustable for very precisely setting the focal position to the working distance, and thus fully exploiting the benefits of scan head calibration. The collimation module can be optionally expanded via a camera adapter for process control and workpiece position detection.

The described, combined scan solution can be deployed very cost-efficiently for numerous applications, e.g. welding processes in the growing field of battery manufacturing.

- Contact Information

- Name: Erica Hornbogner

- Email: info@scanlab.de

- Website: www.scanlab.de