28 April 2017

Sheet metal subcontractor opens On the Wirral with Bystronic equipment

Combining the engineering expertise of company directors Ian Hazlehurst and Russ Canner, a new and expanding specialist manufacturing centre and sheet metal subcontractor, Proform Group, has opened on the Wirral, Merseyside.

Through his own subcontracting firm Machfab Engineering, established in 2004, Mr Hazlehurst has an extensive background in traditional precision engineering. He recently joined forces with Mr Canner, a business entrepreneur, as they identified a gap in the local market for a full-service firm able to provide a full range of services including sheet metal cutting, bending, fabricating and even powder coating.

Through his own subcontracting firm Machfab Engineering, established in 2004, Mr Hazlehurst has an extensive background in traditional precision engineering. He recently joined forces with Mr Canner, a business entrepreneur, as they identified a gap in the local market for a full-service firm able to provide a full range of services including sheet metal cutting, bending, fabricating and even powder coating.

With the assistance of a regional growth fund grant, Proform has invested over £2.5 million in extensive premises and purchasing some of the highest specification machinery available on the market today.

The subcontractor has installed MIG and TIG welding bays and bought a nitrogen generation plant to supply the fibre laser machine and another in the future. This cutting gas, provides a high-quality cut edge. Oxygen will be used only on sheet over 6 mm thick and when cutting copper.

Mr Hazlehurst said, “We polled over 30 of Machfab’s customers and found that they were spending £1.5 million on buying in laser cutting services, so we reasoned that we could win a proportion of that.

“It was also apparent that the general standard of service provided could be improved upon. Through experience at Machfab of buying in laser cutting services, we noticed that quality was sometimes suspect and turnaround times were often much longer than promised.

“These were the factors that prompted Russ and me to set up Proform. It is our intention to be a serious contender and take the subcontract sheet metalworking market in the North West by storm.”

An important facet of the company is that it offers an all-encompassing design and manufacturing service, which was the rationale for investing in laser cutting, water jetting and folding from the outset. It is also the reason for opting to buy Bystronic equipment, as it was the only manufacturer able to supply all three types of machine, which are built in Switzerland at the company’s factory in Niederoenz.

An added bonus is that all equipment uses the same production planning and control software, BySoft 7. It means that programs can be generated from a CAD model to drive the three different types of Bystronic machine, so components can be transferred easily from one to another with little production downtime.

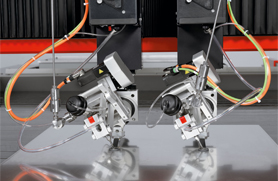

The software incorporates IGEMS, which generates toolpaths over 3D models for machining with the two CNC heads on the waterjet cutting machine. The ByJet Flex has a 6 metre by 3-metre bed, making it the only machine of its type and size in the north of England. All other Bystronic machines of this size and specification are in the south. Any material up to 30 cm thick can be cut to very high accuracy.

The ByStar Fiber laser cutting centre also has a generous capacity of 4 metres by 2 metres, rather than the normal 3 metres by 1.5 metres, and was the first machine of this size to be delivered by Bystronic into the UK market. Its 6 kW fibre laser source can cut 25 mm thick mild steel and 30 mm stainless steel and aluminium, as well as 15 mm copper and 12 mm brass.

The machine has been equipped with a ByTrans sheet handling system capable of delivering material automatically to the machine’s shuttle table and subsequently retrieving the processed sheet. Apart from eliminating arduous manual sheet handling, it has the potential to boost output considerably, as it can be stocked with up to six tonnes of material to allow unattended production overnight.

The press braking function at the Prenton factory is the remit of an Xpert 250 tonne machine capable of bending components up to 4.1 metres long and an Xpert 40, the supplier’s smallest model, of 40 tonnes / 1-metre capacity. Around half of the output from the laser cutting centre is folded on these two machines.

The press braking function at the Prenton factory is the remit of an Xpert 250 tonne machine capable of bending components up to 4.1 metres long and an Xpert 40, the supplier’s smallest model, of 40 tonnes / 1-metre capacity. Around half of the output from the laser cutting centre is folded on these two machines.

Mr Hazlehurst stated that an integral feature of the larger CNC press brake is the large depth of the back gauge, which maximises the range of parts that can be produced. He also appreciates the LED lights along the upper beam that show where the bending tools should be placed for any particular job, as well as the cameras at either side of the machine verifying that the correct punch and die have been selected. The result of these safety measures is that damage to tooling is avoided and scrap is eliminated.

Regarding the Xpert 40, highlights are its user friendliness and sheer speed when bending parts up to one metre, particularly of the CNC back gauge fingers. The 25 mm/s stroke is two and a half times faster than on the Xpert 250, the tooling is interchangeable and power consumption is low.

This also goes for the fibre laser cutting machine, which draws about one-third of the electricity consumed by a CO2 laser. Mr Hazlehurst anticipates that the fibre machine will generate two-thirds of the company’s turnover. It is up to three times faster than a CO2 equivalent, especially on thinner gauges, and is able to cut a wider range of materials without risk of damage to the optics.

Proform held an open day on 21st April 2017 to open the new Prenton premises officially and launch the company’s services. Mr Hazlehurst, a keen Tranmere Rovers supporter, persuaded the club’s chairman, Mark Palios, to officiate alongside the Mayor of Wirral, Councillor Pat Hackett.

- Contact Information

- Name: David Larcombe

- Email: david.larcombe@bystronic.com

- Website: www.bystronic.co.uk/en/