17 February 2019

RADAN trials improve efficiency for Lasershape

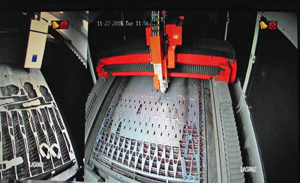

A sheet metal subcontractor has recently switched over to RADAN to drive its fleet of four laser cutters and two water jets, after an intensive three months of development, trials, tests and training.

A sheet metal subcontractor has recently switched over to RADAN to drive its fleet of four laser cutters and two water jets, after an intensive three months of development, trials, tests and training.

Jason George, I.T. and Facilities Manager at Nottinghamshire-based Lasershape Ltd., says their Return on Investment in RADAN looks likely to be achieved within two and half months of starting to use it. Manufacturing components primarily for the general engineering, aerospace, rail and automotive industries, Lasershape's core products are laser cut, folded and powder coated, with some assembly where required, and include parts for almost every sector of industry.

Mr George has been implementing a series of measures over the last two years aimed at driving down costs, and felt their CAD/CAM package was falling behind in terms of efficiency. “The system was very manual, and although we had a project with our supplier who was trying to automate it, we simply couldn’t rely on the results it was producing, and had to have an operative watching over it, which defeated the object.”

They opted to replace it with RADAN, and found in numerous trials that it led to considerable savings. “We use around £400,000 worth of material a month, and with the previous CAD/CAM package our scrap rate was around 20-30 per cent. We compared a trial we ran through RADAN with what our production team had actually sent to the shop floor after making manual changes to improve the nest from the previous system…and it still reduced wastage by approximately 15 per cent.”

They also log the reason for every scrapped part, and he says poor sequencing was the biggest single cause under the old system, which was not producing the high standard they require. “With the large number of parts we produce, it’s impossible to go through each nest and manually select the cutting sequence…we have to rely on automation. We ran the same job through RADAN – and I even tried to trick it, but it was much better at getting out of areas without crashing the head.

“RADAN’s not just about speeding our processes up, it’s all about accuracy, both in terms of the cutting sequence, and the finished component.”

Another test involved a production job of 400+ runs of 3mm aluminium parts in RADAN. “This particular job had ‘head collision’ written all over it. But RADAN cut each sheet 52 minutes quicker than the old system, and with no collisions. When I looked at the code I saw this was because RADAN was able to cut at full speed, while the other software applied slower cutting conditions for small features. This could save us considerable time.”

And an optimised RADAN nest in one of their early trials saved over five hours compared with their previous nests, which he says represents shaving a full minute off each part. Jason George says the RADAN trials and tests gave consistent results and has reduced the task of producing nests to what he calls ‘a simple admin role’ as the system automatically creates efficient, cost-saving nests. “As everything we do now is about efficiency and data capture, RADAN is a key, integral part of the business.”

- Contact Information

- Name: Marc Freebrey

- Email: marc.freebrey@verosoftware.com

- Website: www.hexagon.com