28 May 2008

Rofin Laser on Sparkling Form

The use of lasers for the production of jewellery and other fine objects is in itself not uncommon. What can now be revealed however is the contribution made by Rofin in the creation of the “world’s most expensive piece of art”.

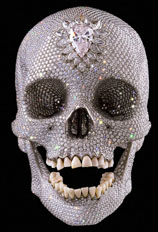

Damien Hirst’s diamond-encrusted skull officially became the world’s most expensive piece of contemporary art, after it was bought in August 2007 by an unnamed investment group for £50 million. The skull, entitled “For the Love of God”, was created for the artist by Bentley & Skinner of Bond Street, London using over 8,601 of the world’s most perfect, flawless diamonds and 2,156 grams of platinum. The creation of the piece took 18 months of dedication and hard work by Bentley & Skinner and the skull also has the distinction of being the largest diamond piece commissioned since the Crown Jewels.

Damien Hirst’s diamond-encrusted skull officially became the world’s most expensive piece of contemporary art, after it was bought in August 2007 by an unnamed investment group for £50 million. The skull, entitled “For the Love of God”, was created for the artist by Bentley & Skinner of Bond Street, London using over 8,601 of the world’s most perfect, flawless diamonds and 2,156 grams of platinum. The creation of the piece took 18 months of dedication and hard work by Bentley & Skinner and the skull also has the distinction of being the largest diamond piece commissioned since the Crown Jewels.

Technology, innovation and skill combine for art

An original 18th century skull of a mid-30-year-old man was used to make a cast before 32 individual platinum plates were created and subsequently joined together using a Rofin StarWeld Performance laser welding system. The design and configuration of the StarWeld Performance laser welder allowed the skill and innovation of the craftsman to be enhanced by the precision joining technology of the laser. The individual components are held in the hands underneath the laser beam, with the precise location of the laser weld accurately viewed through a microscope, thus ensuring accurate and perfect welds each time. The welding process was repeated until all of the 32 plates were joined, forming the setting piece for the diamonds.

Manual laser welding allows platinum, and other precious metals such as gold, silver, stainless steel and titanium to be joined together without the use of soldering. A laser weld is strong and pure even in areas where it would be hard to gain access using other joining techniques. More often than not if you can see the joint you can weld it and the resultant welds have superior strength when compared with welds produced by conventional welding and brazing techniques.

such as gold, silver, stainless steel and titanium to be joined together without the use of soldering. A laser weld is strong and pure even in areas where it would be hard to gain access using other joining techniques. More often than not if you can see the joint you can weld it and the resultant welds have superior strength when compared with welds produced by conventional welding and brazing techniques.

StarWeld Performance is renowned as the bestselling manual laser welding unit with more than 4,500 systems installed worldwide. It is also become the laser of choice for precious metal welding in jewellery workshops and dental laboratories within the United Kingdom. Using StarWeld Performance, seam welds of less than 100 µm can be achieved and materials as thin as 10 µm or wires of 20 µm in diameter can be processed.

StarWeld Performance, the latest jewellery workshop laser welder from Rofin-Baasel

Simple to Operate

Learning to use the laser is quick and easy, and when welding platinum excellent results are achieved with low power and without oxidisation so there is normally no additional finishing required. Adjusting the spot size and laser parameters is easy using joysticks inside the welder. The workpiece is viewed using a stereo microscope and the position of the laser weld is precisely set using a fine cross hair. Laser firing is initiated using a remote footswitch, allowing the hands to remain free to position the part in the weld area. Following a short training course, an inexperienced operator can achieve excellent results.

Learning to use the laser is quick and easy, and when welding platinum excellent results are achieved with low power and without oxidisation so there is normally no additional finishing required. Adjusting the spot size and laser parameters is easy using joysticks inside the welder. The workpiece is viewed using a stereo microscope and the position of the laser weld is precisely set using a fine cross hair. Laser firing is initiated using a remote footswitch, allowing the hands to remain free to position the part in the weld area. Following a short training course, an inexperienced operator can achieve excellent results.

Even a novice can proficiently weld after a little training

Rofin offers a complete range of lasers including CO2, YAG, Vandate and Fibre Lasers. Rofin also provides solutions for laser cutting and marking applications.

Rofin-Baasel UK Ltd

Sopwith Way

Daventry

Northamptonshire, NN11 8PB

Tel +44 (0) 1327 701 100

Fax +44 (0) 1327 710 110

www.rofin.co.uk

About Bentley & Skinner

Bentley’s has been in Bond Street since 1934 and has been in the same family for three generations. Skinner & Co was established in 1880 and was first invited to supply jewellery to the Royal Family in the latter years of Queen Victoria’s reign. Bentley & Skinner, Jewellers by Royal Appointment to both Her Majesty the Queen and His Royal Highness the Prince of Wales, have between them been buying and selling beautiful jewellery for over 180 years. Today Bentley & Skinner continues in the tradition that has helped to make Bond Street a synonym for all that is excellent in the civilised world.

All diamonds supplied by Bentley & Skinner have been purchased from legitimate sources, not involved in funding conflict and in compliance with United Nations resolutions. Bentley & Skinner guarantee that all of the diamonds in the model skull are conflict-free, based on personal knowledge and written guarantees provided by the supplier of these diamonds.

- Contact Information

- Name: David MacLellan ? Sales Manager ? Micro Division

- Email: sales@rofin-baasel.co.uk