3 April 2013

Versatile all metal mirrors

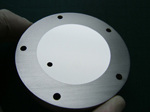

Laser Beam Products’ all metal mirrors are ideal for scientific instruments and OEMs. They eliminate the need for mounts and all the problems and cost that they involve. An all metal mirror like this pictured Aluminium one can have mounting holes, dowel pins, and in this case a through hole in the optical surface itself. It is also possible to machine O ring grooves into the mirror if needed, both on the face and around the circumference.

Laser Beam Products’ all metal mirrors are ideal for scientific instruments and OEMs. They eliminate the need for mounts and all the problems and cost that they involve. An all metal mirror like this pictured Aluminium one can have mounting holes, dowel pins, and in this case a through hole in the optical surface itself. It is also possible to machine O ring grooves into the mirror if needed, both on the face and around the circumference.

LBP’s plated coatings such as electroless nickel and gold cover all the mirror surfaces including the internal surface of holes, so chemical resistance is maintained. With sealed CO2 lasers, these types of plated coatings are specified as they prevent the pure laser gas from being denatured by exposure to copper. LBP believes that laser gas can undermine thin film optical coatings at the copper/coating interface, causing the coating to peel or lift.

There is a small gallery of metal laser mirrors on the LBP web site. If you are an optical engineer it may give you some idea of what is possible with all metal mirrors. Because LBP’s mirrors are chemically polished to a surface smoothness normally only available on UV grade mirrors, there are none of the diamond machining arcs, ripples, or chatter on the surface that degrade optical performance.

- Contact Information

- Name: Mark Wilkinson

- Email: sales@lbp.co.uk

- Website: www.lbp.co.uk