17 September 2015

TRUMPF develops pulsed, green laser for welding copper

With the TruDisk 421 pulse, copper welding is more efficient, generates fewer spatters and achieves greater reproducibility of the welded seam, regardless of the nature of the surface.

With the TruDisk 421 pulse, copper welding is more efficient, generates fewer spatters and achieves greater reproducibility of the welded seam, regardless of the nature of the surface.

TRUMPF has developed a pulsed, green laser for efficient welding of copper, the TruDisk 421 pulse. This new disk laser, in pulsed mode, operates at the mean power of 400 Watts, generating laser light at 515 nanometers. Light in the green spectrum solves the problems previously experienced when using infrared lasers to weld copper.

The problem is infrared

Copper is an excellent conductor of both heat and current, making it a metal for many applications. Its advantages are put to use in the widest variety of industries and sectors. In addition to medical technology and the automotive, chemical and foods industries, copper is indispensable to electronics and electrical technology.

Due to ever more compact housings and the higher performance capacities of electronic components, demands on the production and joining technologies for copper components are also rising.

When using the laser to weld copper, beam sources with an infrared wavelength are commonly used. The two greatest challenges here are good reproducibility and low spattering. At a wavelength of 1,000 nanometers (IR), copper is highly reflective. Uniform welding seams – which will depend on the surface properties – can be guaranteed only to a certain degree, a degree that is often not sufficient for industry.

Spattering is a problem during deep welding. These spatters can damage the component and, in the worst case, cause short circuits on the board. Both can be countered by properly matching the laser parameters – such as the distribution of power density, the pulse width and the shape of the vapour channel. But despite this, the results are often still less than ideal.

What cannot be influenced are the surface tension and viscosity of copper. Both properties are lower, when compared with steel and they lead to a less stable weld pool. This is aggravated by increased energy loss due to the high thermal conductivity of copper. The pulsed green laser from TRUMPF brings about a considerable improvement in the process.

The solution is green and pulsed

To generate the green wavelength in the TruDisk 421 pulse, the frequency of the laser beam is doubled inside the laser resonator. The advantages of this green laser are many and varied. Copper absorbs the green light far better than the infrared. This means that the material reaches its melting temperature faster, the welding process starts quicker, and less laser power is required.

While the infrared laser works with 2.6 kilowatts of peak pulse power, the green laser requires only 1.4 kilowatts for the same welded seam. The process is more energy-efficient and far fewer spatters are formed. The green laser also improves the reproducibility of the results. Regardless of whether the surface is oxidized, ground, sandblasted, rough or polished to a high gloss – with green laser beams the copper welding seams can always be made at uniform quality.

Among the reasons for this is that absorption at room temperature is independent of the surface properties. The use of shielding gases like argon and nitrogen will result in a welded seam of even higher quality. These shielding gases can be used efficiently and sensibly only when welding with the green laser. When using the inferior infrared alternative, the surface of the weld pool reflects more strongly because of the gas. This means that greater laser power is necessary for welding.

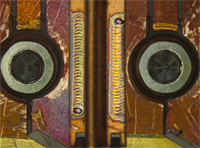

Image: Direct copper bonding (DCB)

The uniformity of the welding depth when using the TruDisk 421 pulse makes it possible to weld thin materials on a difficult substrate. Shown in the illustration: Two copper layers of differing thicknesses (0.2 and 0.3 millimetres) are welded without damaging the ceramic material lying below.

- Contact Information

- Name: Gerry Jones

- Email: gerry.jones@uk.trumpf.com

- Website: www.uk.trumpf.com