4 February 2016

Carr's laser welding for classic cars

Many classic cars only have a belt driven cooling fan. This vital cooling mechanism is old-fashioned and makes the cars prone to over-heating, especially while queuing in traffic with the engine idling. Revotec, however, are able to solve this problem by making an electronic controlled fan cooling system which can be fitted to these cars allowing the radiator to be cooled, in all conditions.

Many classic cars only have a belt driven cooling fan. This vital cooling mechanism is old-fashioned and makes the cars prone to over-heating, especially while queuing in traffic with the engine idling. Revotec, however, are able to solve this problem by making an electronic controlled fan cooling system which can be fitted to these cars allowing the radiator to be cooled, in all conditions.

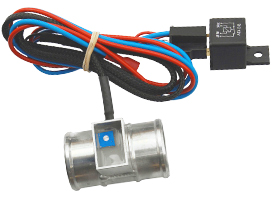

Carrs’ role in this process is welding the sensor housing, called a tube insert (see image), for Pace UK Ltd. This sensor is used to detect the temperature of the water pumping through the hose determining whether or not to start the fan. For their function, it is vital that these parts are thin to be able to react to the temperature quickly and efficiently. However, being thin makes the parts vulnerable to over heating in TIG welding, therefore laser welding is the best option for the job. The tube insert, a 5000 grade of aluminium, is welded with a filler wire to make a nice fillet joint and strong weld.

These cooling systems are fitted to classic cars like Jaguars and Triumphs, which do not have the luxury of an electronic cooling fan. This new technology from Revotec, enables the engines of classic cars to survive our modern day conditions.

- Contact Information

- Name: Phil Carr

- Email: pc@carrswelding.co.uk

- Website: www.carrswelding.co.uk