14 October 2016

Rofin - Industrial Laser Marking and Welding of Plastics

2nd generation 3D marking solution enters new performance class

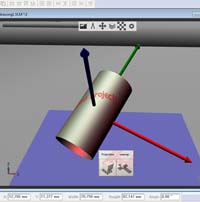

With its new VLM (Visual Laser Marker) 5.3 release ROFIN offers an exceptionally powerful solution for 3D marking of irregularly shaped surfaces. All 3D tools and the required WYSIWYG viewer have been integrated into VLM, which now, for instance, visualizes the angle of incident and handles flexible calculation and preview of axis kinematics. VLM now offers Unwrapping, a very promising alternative to parallel-projection for calculating 3d marking layouts. It’s based on the UV mapping algorithm which is used for mapping two-dimensional images onto arbitrarily shaped objects. The user just selects projection method and surface (VLM imports all common CAD file formats) and the laser marking software calculates and visualizes the marking result. Z correction data is no longer required.

Additionally, ROFIN will integrate new powerful 3D scanners upon request. The scanners can be used for capturing the marking surface as well as for automated position correction in series production. After scanning and teaching the reference part, the control software will detect position deviations of subsequent pieces and automatically adjust the marking layout.

Market-leading manufacturers are counting on ROFIN’s polymer welding solutions

In addition to its stand-alone solutions based on the successful MPS laser workstations, ROFIN focuses on flexible integration packages for polymer welding. As always, ROFIN offers customer-tailored complete solutions from a single source. This includes application evaluation and design, selection of suitable laser sources, design of customer-specific clamping devices, control software configuration with integrated collapsing height measurement and visualisation, production line integration and commissioning.

- Contact Information

- Name: Andrew May

- Email: a.may@rofin-baasel.co.uk

- Website: www.rofin.co.uk