22 January 2017

No Glue Femtosecond Laser System by TRUMPF

A major challenge was posed for economical, high-quality laser-welding for glass until laser specialist, TRUMPF developed a Femtosecond Laser System that replaces conventional joining processes such as gluing. The advantage: in contrast to gluing processes, is that no additional materials that are susceptible to evaporation or embrittlement are required, reducing costs and increasing durability, as well as stability of the seam. The special nature of glass poses considerable challenges with regards to processing: glass is hard and brittle, has lower thermal conductivity than metal and tends to crack when heated unevenly due to the internal tension developed. Femtosecond laser systems can prevent such cracking. “The laser system must permit variable programming of pauses and pulses,” explains Elke Kaiser, applications engineer at TRUMPF.

A major challenge was posed for economical, high-quality laser-welding for glass until laser specialist, TRUMPF developed a Femtosecond Laser System that replaces conventional joining processes such as gluing. The advantage: in contrast to gluing processes, is that no additional materials that are susceptible to evaporation or embrittlement are required, reducing costs and increasing durability, as well as stability of the seam. The special nature of glass poses considerable challenges with regards to processing: glass is hard and brittle, has lower thermal conductivity than metal and tends to crack when heated unevenly due to the internal tension developed. Femtosecond laser systems can prevent such cracking. “The laser system must permit variable programming of pauses and pulses,” explains Elke Kaiser, applications engineer at TRUMPF.

Glass is permeable to light with wavelengths ranging from ultraviolet to near infrared. Absorption takes place only when the energy densities are very high, so that processing within the glass is facilitated. The highest performance density lies deep in the lower glass at the focal point. The energy from several thousand laser beam pulses causes a melt pool to be created and pushed upwards in just a few milliseconds. Skillful thermal management and an optimal ratio of pulses and pauses prevent the glass from cracking.

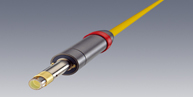

Protective Caps for Laser Light Cables Are Laser-Welded Instead of Glued

Glass components that were previously glued to each other can now be economically welded with high-quality results, as TRUMPF has demonstrated in its own production of laser light cables. Until recently, the lids of the protective caps for the laser light cables were glued on. Now, lasers are used to weld them on. The joint strength of the glass parts depends primarily on the level of pulse energy. The pulse energy for 1030 nanometer infrared light needs to be 9 microjoule.

TRUMPF is currently building a laser-welding system for reliable glass welding for mass production of the protective caps for the laser light cables in its own production plant in Schramberg. Elke Kaiser states, “The laser system also serves as a pilot system to demonstrate to potential users that new, innovative laser methods are reliable and ready for deployment in glass processing and offer immense advantages.” The new laser welding methods for glass prove their economy and efficiency by eliminating the disadvantages of conventional methods such as gluing: optical beam paths are no longer contaminated, there is no evaporation and no long-term embrittlement of adhesives, which means that the protective caps made of glass will be considerably more durable. TRUMPF is currently preparing further applications for the laser welding of glass for use in its own production.

- Contact Information

- Name: Gerry Jones

- Email: gerry.jones@uk.trumpf.com

- Website: www.uk.trumpf.com