3 April 2017

ULO Optics and TWI help to bring laser-based additive manufacturing to the mainstream

AILU members TWI and ULO Optics are collaborators in a EUR 2.4 million Horizon 2020 project (ModuLase) which aims to develop and validate a modular re-configurable Laser Process Head. UK subcontractor Graham Engineering and European companies from the Netherlands, Spain, Belgium, Italy and Germany are also project partners.

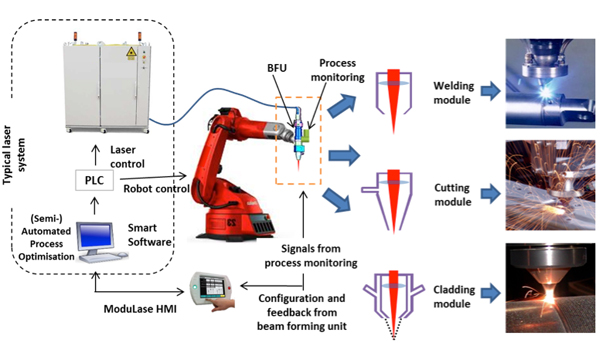

The ModuLase project will develop a re-configurable highly flexible processing head system, which will be capable of covering welding, cladding and cutting, with a changeover time of less than one minute between processes. The new head system will achieve this through the use of three modular end-effectors and, will include intelligent sensor technologies for in-process monitoring. Lastly, since linked to an intelligent system, the ModuLase system will achieve adaptive process control, quality assurance and semi-automated process parameter configuration.

Schematic overview of the ModuLase system

ModuLase will encompass all stages of the process chain and provide additional flexibility, cost reduction and execution speed without compromising the overall quality, hence providing a better overall performance. By providing the groundwork for a more thorough utilisation of laser-based manufacturing, ModuLase will provide a critical tool for the Factories of the Future public-private partnership which sets a vision and outlines routes on its 2014-2020 roadmap towards high added value manufacturing technologies. As result of this vision, the factories of the future will be clean, highly performing, environmental friendly and socially sustainable.

The ModuLase project has received funding by the Photonics and Factories of the Future (FoF) Public Private Partnership (PPP), under grant agreement No. H2020–FoF-2016-723945-ModuLase. The project is an initiative of the Photonics and Factories of the Future Public Private Partnership.

- Contact Information

- Name: Paul Maclennan

- Email: paul.maclennan@ulooptics.com

- Website: www.ulooptics.com