7 June 2017

SCANLAB's calibration solution improves laser processing quality

In laser processing, highest quality is of capital concern. The more expensive the processed components and shorter the allotted processing time, the more crucial it is to avoid rejects from the get-go. To this end, SCANLAB has added the CALsheet program to its line of calibration solutions. The software enables simple correction of system-specific errors. With just a few steps, custom correction files can be generated that improve processing accuracy to as good as 30 μm.

In laser processing, highest quality is of capital concern. The more expensive the processed components and shorter the allotted processing time, the more crucial it is to avoid rejects from the get-go. To this end, SCANLAB has added the CALsheet program to its line of calibration solutions. The software enables simple correction of system-specific errors. With just a few steps, custom correction files can be generated that improve processing accuracy to as good as 30 μm.

Materials processing and marking applications via scan systems with an F-Theta objective and two mirrors on galvo scanners will produce characteristic image field distortions, also known as pincushion and barrel effects. Wherever SCANLAB scan systems are driven by RTC control boards, these inaccuracies and system-specific properties can be compensated via a new calibration solution in just a few steps.

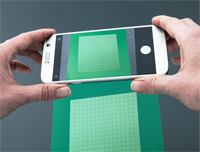

A paper test sheet is laser marked and then overlaid with a transparent, grid-structured glass master. The marked sheet with overlaid master is then photographed, either simply via a smartphone or with a flatbed scanner for even more precise results. As soon as the image is transferred to the calibration software, a custom correction file can be calculated from it. When laser processing again with this correction file, accuracy improves to 50 μm when a smartphone photo was used, or 30 μm for a flatbed scanner image. The entire procedure of optimising process results takes only a few minutes.

- Contact Information

- Name: Erica Hornbogner

- Email: info@scanlab.de

- Website: www.scanlab.de