14 July 2017

EOS releases EOSTATE Exposure Optical Tomography for real-time monitoring of metal-based 3D printing

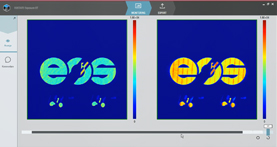

EOS, the technology provider for industrial 3D printing of metals and polymers, is expanding its EOSTATE monitoring suite to include an additional tool. EOSTATE Exposure OT, the first commercial system for optical tomography worldwide, now provides real-time, camera-based monitoring of the additive, metal-based build process, based on the EOS M 290 system. The solution fully maps each part throughout the build process, layer by layer, regardless of its geometry and size.

EOS, the technology provider for industrial 3D printing of metals and polymers, is expanding its EOSTATE monitoring suite to include an additional tool. EOSTATE Exposure OT, the first commercial system for optical tomography worldwide, now provides real-time, camera-based monitoring of the additive, metal-based build process, based on the EOS M 290 system. The solution fully maps each part throughout the build process, layer by layer, regardless of its geometry and size.

Dr Tobias Abeln, Chief Technical Officer (CTO) explains: “With EOSTATE Exposure OT, we are offering companies an even more comprehensive process monitoring and quality assurance. As such, we are helping customers meet the stringent inspection requirements for each component, particularly in sectors such as aerospace." He continues: “Quality assurance is essential in large-scale manufacturing where reproducible component qualities are of prime significance. Costs for quality assurance are significantly reduced as the monitoring process occurs early on at the build process stage. This has a positive impact on costs-per-part as well."

- Contact Information

- Name: Garth Stevenson

- Email: garth.stevenson@eos.info

- Website: www.eos.info/en