24 August 2018

TLM supplies new laser marking system with "Point-and-shoot" technology

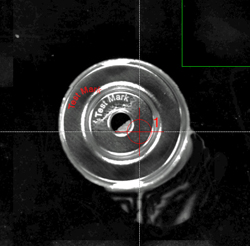

The quality, durability and flexibility of laser marking are just a few of the attributes that continue to drive the growth of this technology. Another is the ability of the laser to produce small yet legible marks on a diverse range of materials. EMP has seen a continued trend for both laser marking on smaller parts and also an increasing numbers of requests to produce miniature laser marking content, sometimes as small as just 0.5 mm in height.

The quality, durability and flexibility of laser marking are just a few of the attributes that continue to drive the growth of this technology. Another is the ability of the laser to produce small yet legible marks on a diverse range of materials. EMP has seen a continued trend for both laser marking on smaller parts and also an increasing numbers of requests to produce miniature laser marking content, sometimes as small as just 0.5 mm in height.

Although the laser is more than capable of achieving this demanding specification, manually positioning and aligning the component for marking becomes more challenging as the parts and laser mark become smaller. This is where FOBA Laser’s Point & Shoot™ concept comes into its own, making it easy for the user to position the marking contents on the products to be marked.

The Point & Shoot™ camera system views through the lens on the marking field, creating an image of the component and displaying it in the user interface. The user then simply creates the marking information required and positions it (via ‘drag & drop’) at the exact position on the product where it needs to be applied. This WYSWIG camera-guided laser marking process leads to a reduction in the number of defective products, higher efficiency and productivity, as the marks, even tiny ones, are always applied at the desired location and in the specified manner. There is also a verify function prior to and following laser marking. Additional benefits of this system are the fact that no expensive fixturing is required and there is no trial and error process, saving both time and cost.

- Contact Information

- Name: Andy Toms

- Email: andy@tlm-laser.com

- Website: www.tlm-laser.com